Description

FEATURES

- Real-time detection to aid operators in identifying suspicions

- High performance – typical penetration up to 1.8 ” of steel

- Startup with fingerprint

- Four layers of lead curtain

- Uninterruptible power supply

- Equipped with input & output rollers

- Adjustable conveyor speed

- Real-time remote monitoring system

- Luggage image and walk-through metal detector status display on the same screen

- Entry and exit roller tables

SOFTWARE FEATURES

- Perfect View (PV)

- Black / White (B/W)

- Pseudo Colors (PS)

- Inverse View (IN)

- High Penetration (HP)

- Real-time Image Processing and Image Zoom (64x)

- Image of Previous Baggage

- Programmable Function Keys

- Baggage Counter

- Date / Time Indicator

- Threat Image Projection (TIP)

OPTIONS

- Operator desk

- Video surveillance

- Gray paint

- Guard plate rollers (two layers of lead curtains)

- Eyes on function (eye-tracking technology to follow the user’s eye as they operate X-ray inspections.

- There will be a prompt when the operator’s eyes leave the screen)

SPECIFICATIONS

- Tunnel Dimensions (W*H): 24in x 16.6in

- Conveyor Speed: 0.008in/sec – 0.02in/sec

- Load on Conveyer: Max 200kg / 441lb (evenly distributed)

- Space Definition: horizontal O.04in vertical O.08in

- Steel Penetration: 1.5″ guaranteed; 1.6in typical Wire

- Resolution: 38AWG guaranteed; 40AWG typical

- Dual-Energy Protector: yes

- Number of Colors in X-ray Image: 3

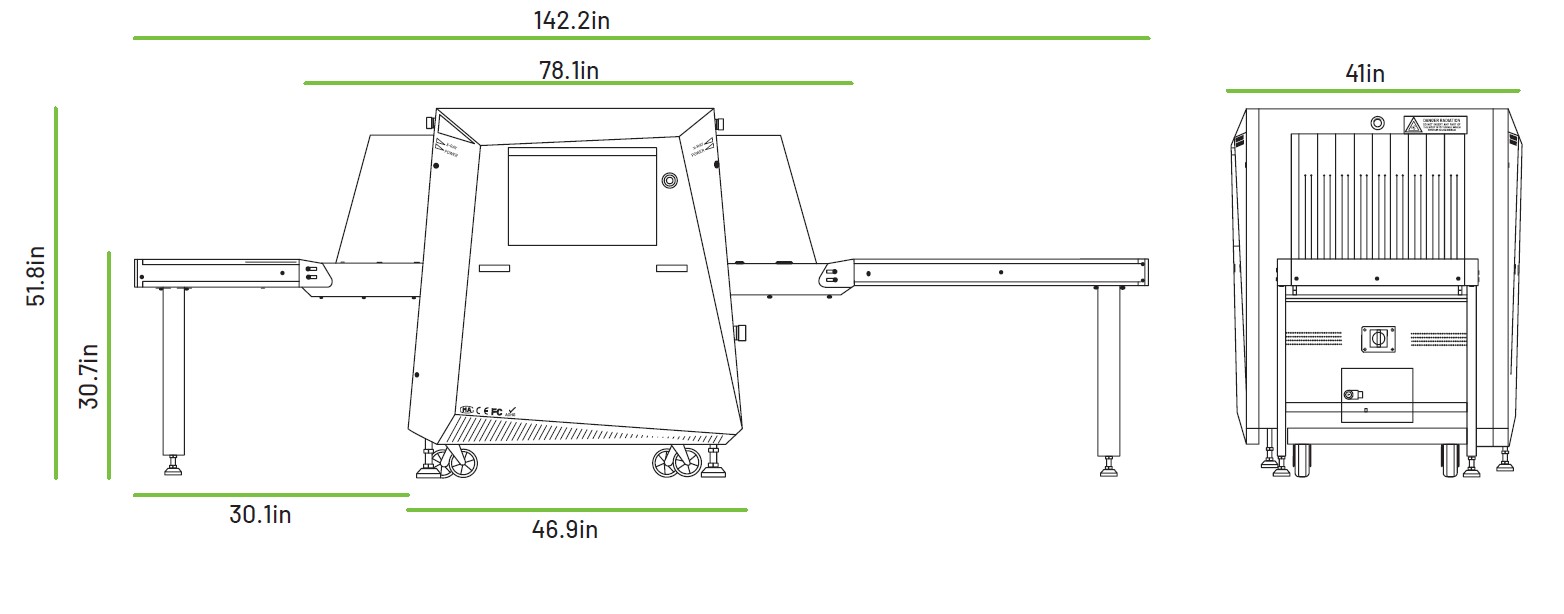

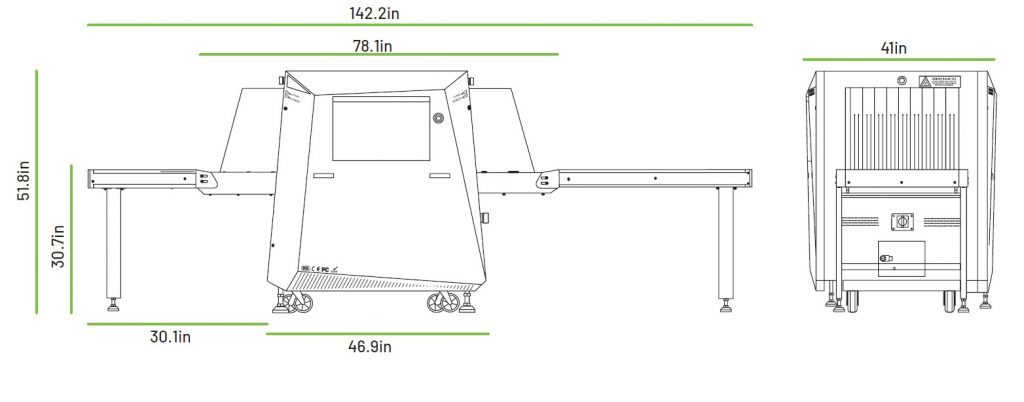

- Dimensions (L*W*H): 142.4in x 41in x 51.8in

- Package Dimensions (L*W*H): 82.7in x 47.2in x 63in

- Package Weight: 750kg / 1654 lb

- Film Safety: ASA/ISO 1600 standard of film safety

- Single Inspection Dosage Rate: <1.0uGyv

- Z-Level Detection (explosives): NO

DRAWING & DIMENSIONS (in)

INSTALLATION

Note: On-site Commissioning of equipment and Training are required by state law in every state of the US. These are not optional items.

Commissioning includes uncrating and preparing the machine for operation, testing the machine and all functions, general operational training of machine (this is not the complete training), Radiation testing, completion of documents to be submitted to the state of installation, and filing with the FDA.

Training – By state regulation there needs to be a RSO (Radiation Safety Officer) per site and the training course is required. There is a mandatory Radiation safety course that is to be taken by every machine operator. The operator training course is required for each machine operator. The mandatory state specific Radiation Protection Program is a manual required to be issued and remain on location of installation.

Training Package:

1 – X-ray Operator Radiation Safety Training 1 person – online 2 hours (Required)

1 – X-ray operator training course per person – online 1.5 hours (Required)

1 – Radiation Safety Officer training course 1 person – online 2 hours (required)

1 – State specific regulatory turnkey Radiation Protection Program (required)

*Please note that crating and freight cost is not included and will be calculated separately. Worldwide freight is available by sea/air/ground.